Plastic Injection Molding Machine For Thin-Wall Products

High-speed plastic injection molding machines feature highly precise hydraulic pressure and flow control systems, effortlessly meeting customer requirements for dimensions, tolerances, and quality of thin-wall plastic products. These machines maintain stability even at extremely high injection speeds, ensuring consistent plastic output in each production cycle. This prevents short shots or flashes, effectively reducing production costs.

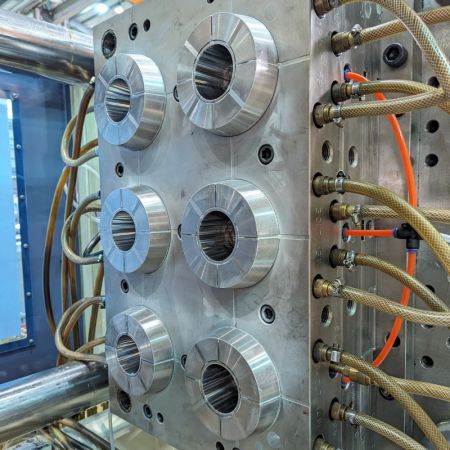

Thin-wall plastic injection molding is widely used in the production of precision instrument parts, electronics, medical devices, communication equipment, and food packaging containers. Due to the thin walls of these products, the high gate resistance of the molds requires high-speed, stable injection performance and a robust clamping structure to achieve efficient output within the shortest cycle time.

The advantages of using high-speed plastic injection molding machines for thin-wall injection molding

Our high-speed injection molding machines are highly acclaimed by customers for their outstanding injection performance, precise control, and rapid response speed. They ensure consistent shot volumes in every cycle, even at extremely high injection speeds.

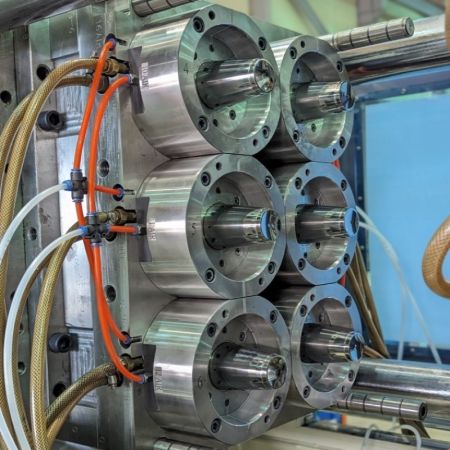

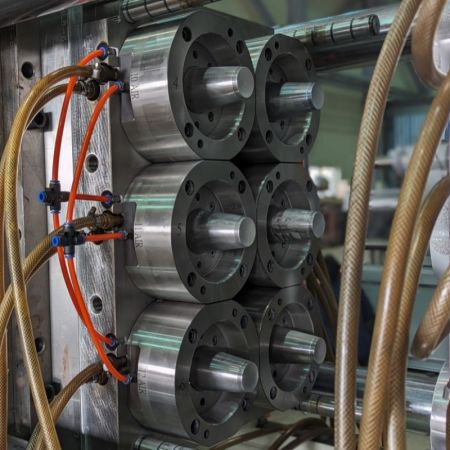

Every high-speed injection machine adopts a servo valve to control the injection system, which includes injection, holding, plasticizing, and back pressure stages. This high-speed servo valve can switch the spool from 0% to 100% in just 26 milliseconds after receiving the signal, enabling precise V/P point switching.

Furthermore, the use of multi-stage P.I.D digital control cards provides different linear outputs during injection, plasticizing, and holding stages. The collaboration between the servo valves and control cards ensures consistent pressure, speed, and holding point switching in every injection stage. Additionally, with the support of an accumulator, the maximum injection speed of the machine can reach up to 360mm/s.

Overall, this high-speed injection molding machine guarantees efficient, precise, and consistent injection performance through advanced control technologies, making it an excellent solution for manufacturing needs that demand high quality and high production efficiency.

Gallerys

- Plastic injection molding machine used for producing 10-ounce disposable PP/PS cups for the airline industry, with a production cycle of 8 seconds.

- High-speed plastic injection molding machine used for producing 7-ounce disposable PP/PS cups for the airline industry.

- High-speed plastic injection molding machine used for producing plastic cups for the airline industry.

- The thin-wall plastic injection molding machine is used to produce plastic cups for the airline industry.

- Related Products

Thin-Wall Plastic Injection Molding Machine

EHIII-DS Series (50~750 TON)

Thin-wall plastic injection molding machine is manufactured by increasing the injection speed and the stability of injection, the thin-wall injection machines effectively avoiding short shots and flashes on the product to improve product quality.We upgrade the thin-wall injection machines control components to get a higher injection speed that ensures the injected melting plastic material could reach the entire mold cave before it getting solidification which decreases the short-shot products happened. If you need more detail of product information or buying consultation, please contact us.

Small Size High Speed Plastic Injection Molding Machine

EHIII SERIES (50~140 Ton)

The small high-speed plastic injection molding machine is from 50 tons to 140 tons. It comes standard with a high-response servo valve and accumulator. During the assistance with the accumulator, the injection rate can reach 360mm/sec. The high-response servo valve detects the actual pressure and position of the injection by the transducer and then catches the feedback signal to adjust the output to reach a perfect closed-loop control. By the precision control of the injection, plasticizing, and holding switch-over to prevent causing flash or short-shot. If you need more detail of product catalog, please reach out to us.

Small Size High Speed Hybrid Plastic Injection Molding Machine

EHIII-DS Series (50~140 TON)

The 50 ton to 140 ton High-Speed Hybrid Plastic Injection Machine with the Bosch Rexroth servo-valve and the Rexroth Injection Molding Process Controller. The controller has rapid response and feedback, and multi-stage of PID control features that enable to control of injection pressure, hold pressure, and backpressure precise. If you need more detail of product catalog, please reach out to us.

Medium and Large Size High Speed Plastic Injection Molding Machine

EHIII SERIES (180~750 Ton)

The High-speed plastic injection molding machine features 180 ton to 750 ton medium and large size and reaches the 360mm/sec injection speed rate by the assist of the accumulator. To control the flow from the accumulator, we use a servo valve to inject, charge and switch the holding pressure point, which makes sure every single injection could inject the same volume of plastic to prevent the flashing or short shot of the products. If you need more detail of product information or buying consultation, please contact us.

Medium and Large Size High Speed Hybrid Plastic Injection Molding Machine

EHIII-DS Series (180~750 TON)

The High-Speed Hybrid Plastic Injection Machine is designed with the Bosch Rexroth servo-valve and the Rexroth Injection Molding Process Controller. The controller has rapid response and feedback, and multi-stage of PID control features that enable to control of injection pressure, hold pressure, and backpressure precise. If you need more detail of product catalog, please reach out to us.