Small Size High Speed Plastic Injection Molding Machine

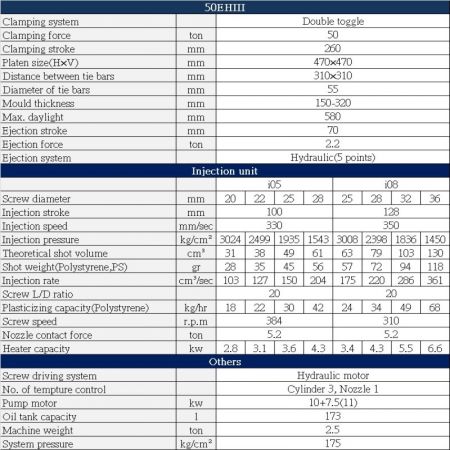

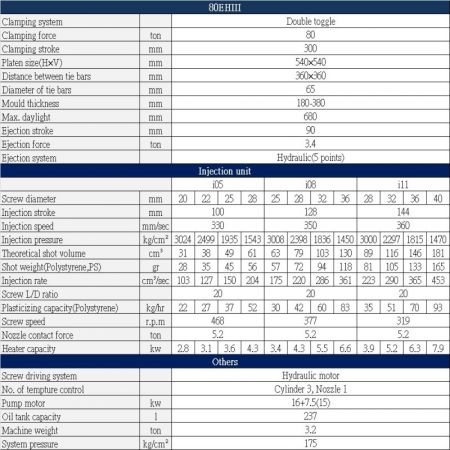

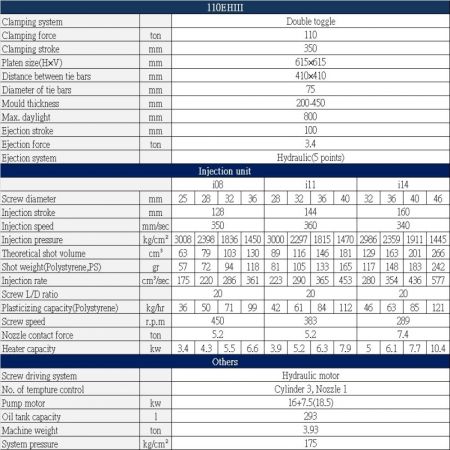

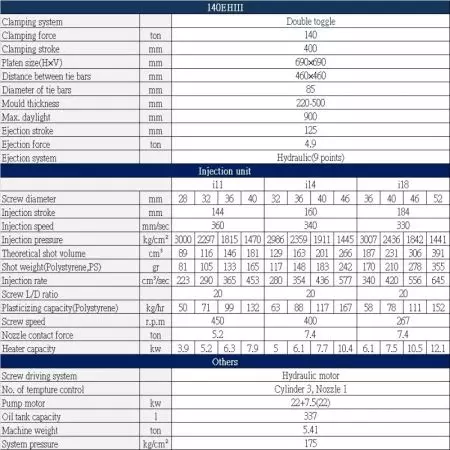

EHIII SERIES (50~140 Ton)

The small high-speed plastic injection molding machine is from 50 tons to 140 tons. It comes standard with a high-response servo valve and accumulator. During the assistance with the accumulator, the injection rate can reach 360mm/sec. The high-response servo valve detects the actual pressure and position of the injection by the transducer and then catches the feedback signal to adjust the output to reach a perfect closed-loop control. By the precision control of the injection, plasticizing, and holding switch-over to prevent causing flash or short-shot. If you need more detail of product catalog, please reach out to us.

Plastic injection machine, Injection Molding Machine for plastics

Plastic Injection Molding Machine Core Features

- Clamping force from 50 ton -140 ton.

- Injection with dual hydraulic cylinders.

- Response time of servo valve signal from 0% to 100% only needs 26ms.

- Maximum injection speed rate is up to 360mm/sec.

- OLAER pressure accumulator.

- We supply multiple solutions to upgrade the system for our customers to achieve the goal of significantly shortening the production cycle.

Your Benefits of purchaseing Plastic Injection Molding Machine

- High-speed injection, significantly shorts production cycle time and rising output.

- The best choice for thin wall and multi-cavity products.

Our Advantage

- The High-Speed Injection Molding Machine equips the accumulator to boost the injection speed. And built a close-loop in the injection oil circuit system which is controlled by a rapid response servo valve, which makes the injection molding machine is not only high speed but also precise.

- Each pressure accumulator has CE certification with high safety and stable pressure releasing performance.

- The s-60c high carbon steel slide matched the roller bearing reduces the friction and brings smooth during mold opening and clamping.

- Mold open/clamping switch is controlled by a proportional solenoid valve increase the stability of the platen location point.

- The platen uses the FCD-600 spheroidal graphite cast iron could achieve 600 ~ 750 N/mm² tensile strength not easy to bend or deform.

- The toggle automatic centralized lubrication system, always keeps the toggle and copper bushing parts lubricated to increase the life-time.

- The Mold Adjustment Mechanism with sturdy gear and high torque hydraulic motor has high strength and low clearance, which reduces adjusting time and increases accuracy.

- Mold Adjustment Motor with Brake Unit always keeps the platen in the same position prevents to cause the flash of the products.

Related Application

It is suitable for thin-walled or frame products such as food containers and panel frames, which are large injection area but with a small injection amount.

- Specification TableRelated Products