Central system dehumidifying dryer

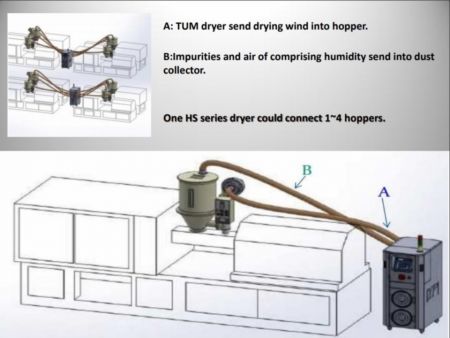

Central system dehumidifying dryer supports a one-to-many system for optional up to four hoppers which is convenient to centralized manage for couples of the injection machines. Suitable for the large amount of production or high-frequency to change plastic material production line.

Dehumidifying dryer Core Features

- One-to-many system for optional (up to four hoppers).

- Suitable for the large amount of production.

Your benefits of purchaseing dehumidifying dryer

- Shortening half of the drying duration.

- Effectively increasing transparency for 3C products, i.e. lens backboards. (PC, PMMA)

- Effectively reducing the generation of gas during the injection molding and effectively reducing the number of cleaning the molds (PA46, PPS) so as to increase mobility.

- Reducing ripples caused by insufficient drying and thus increasing product validity and quality.

- Increasing drying to the raw material to enhance product stretching resistance, intermolecular combining force and hardness. Due to less moisture in the raw material, less resistance is left in the raw material to hinder intermolecular combination.

- Reducing cost for drying equipment and cost for drying plastic materials.

- Saving electricity fee for drying for more than 40%.

- The equipment is able to ensure the water containing rate drops to 0.02%(200ppm) so as to increase product quality.

- There are different reasons for defected products, especially when the plastic material is not fully dried.

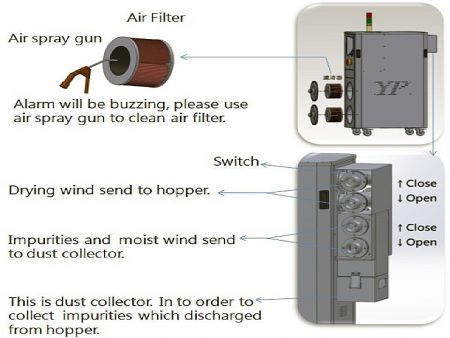

- Easy access two stage cyclonic filter removes fines to 1 micron.

- Standard microprocessor controlled.

- LED lights monitor system functions.

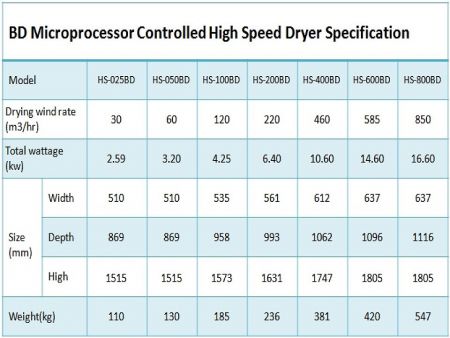

- Specification Table

- Mechanical Structure