Hydraulic Plastic Injection Molding Machine

EH-DS Series (50~750 TON)

The hydraulic plastic injection molding machines has advantage that we provide back pressure to every action by limiting the oil return flow that decreases affection by inertia increases the hydraulic fluidity stability from a high-speed to stop condition. With this advantage, we achieve the precise level of the electric injection molding machine. Furthermore, we still keep the hydraulic injection molding machine's original advantage of high holding pressure ability and stable linearity pressure output. If you need more detail of product information or buying consultation, please contact us.

Plastic Injection Molding Machine Core Features

- Clamping force form 50ton - 750ton.

- The 1:1 pistons scale design of the injection oil cylinder improves the accuracy of injection and shot volume.

- Injection position transducer signal digitization gives an extreme response speed.

- The proportional oil return control increases the stability of mechanical actions that makes the acceleration and deceleration slope more clear to have the capacity to execute precision movements.

Your Benefits of purchaseing Plastic Injection Molding Machine

- The mechanical action is more stable and precision in high-speed shift.

- High consistent, reducing quality control cost.

- Low energy consumption

- Quick and Easy to integrate to the automated production equipment.

- Significantly reduce machine maintenance costs.

Related Application

High-Precision injection machine, its applicable in precision, medical, optics and military industry.

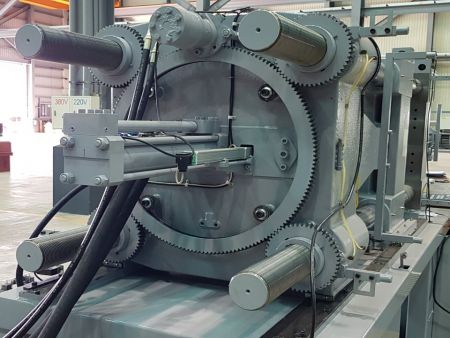

- Machine Pictures

- The injection molding machine adopts strong clamping structure to ensure the stability of quality.

- The injection unit adopts dual injection cylinders, provides high-response speed.

- Injection molding machine adopt a Toshiba servo motor to achieve fast and stable oil control.

- The 1:1 pistons scale design injection oil cylinder, provide stable injection control.

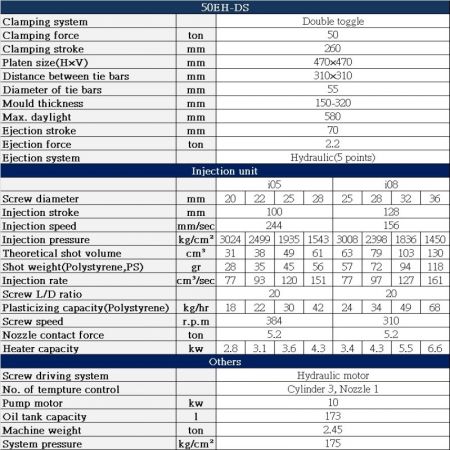

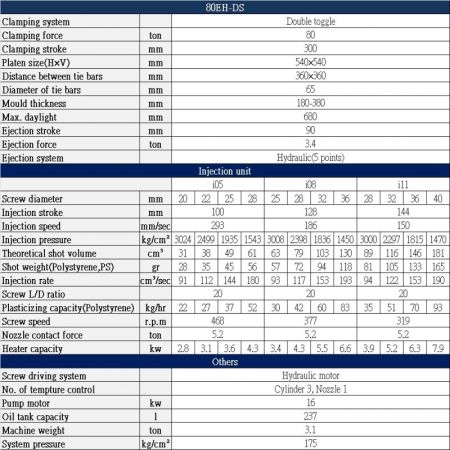

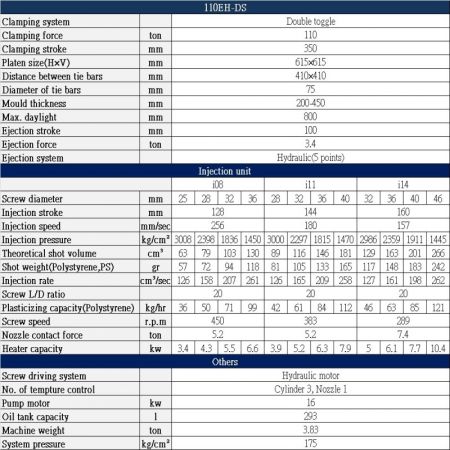

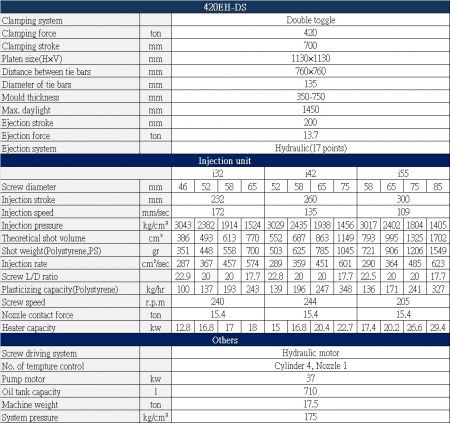

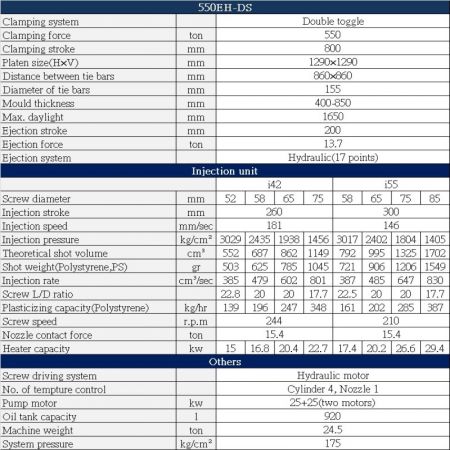

- Specification Table

- EH-DS 50 ton Specification Table

- EH-DS 80 ton Specification Table

- EH-DS 110 ton Specification Table

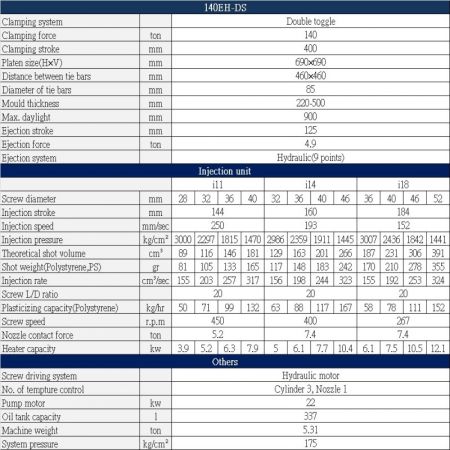

- EH-DS 140 ton Specification Table

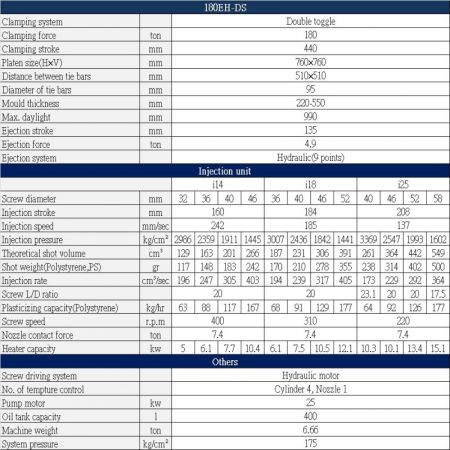

- EH-DS 180 ton Specification Table

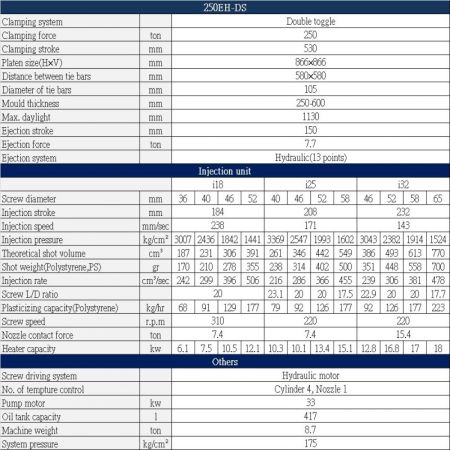

- EH-DS 250 ton Specification Table

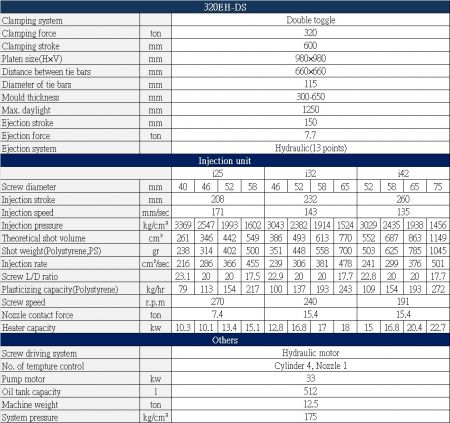

- EH-DS 320 ton Specification Table

- EH-DS 420 ton Specification Table

- EH-DS 550 ton Specification Table

- Related Products

Small Size Hybrid Plastic Injection Molding Machine

EH-DS Series (50~140 TON)

Small size Hybrid Injection Plastic Machine range from 50ton to 140ton equips the servo energy saving system, which achieves an outstanding energy-saving effect. The Hydraulic system with a rapid response and pressure output linear feature, easy to reach every requirement given by the user. Our Injection Machines can provide stable pressure when a high flow rate is required during the production. It saves energy during the low pressure output and the product cooling. Comparing with the conventional hydraulic system, it saves 60% energy consumption. It has a perfect pressure curve repeatability, and still keep the advantage of conventional hydraulic system, that has the ability to keep the pressure at 140kg/cm2 at least 30 sec. with low oil flow, it gives a huge competitiveness of thick products to prevent shrink, bubblers, jetting, etc. If you need more detail of product catalog, please reach out to us.

Medium and large size Hybrid Plastic Injection Molding Machine

EH-DS Series (180~750 TON)

The Hybrid Plastic Injection molding machine (180ton to 750ton medium and large size) equips a high-performance servo motor, which also achieves an outstanding energy-saving effect. With a rapid response and pressure output linear feature, easy to reach every requirement given by the user. It reduces the motor r.p.m when during the low flow is required and the product cooling to save the energy consumption. Comparing with the conventional hydraulic injection machine, it saves 60% energy at least.