Vertical Toggle Hybrid Plastic Injection Molding Machine

V-DS Series (60~150 TON)

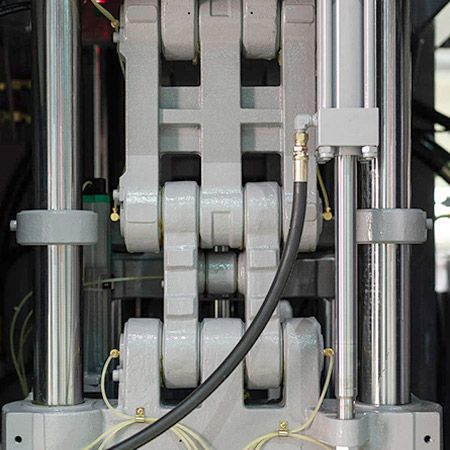

Vertical hybrid Plastic Injection Molding Machine with the toggle clamping system, build in an auxiliary hydraulic cylinder to assist lifting up the platform during clamping to reduce the loading of the toggle and make clamping more quickly, thereby to increase the lifetime, this mechanical structure also prevents when high-speed clamping causes the collision of the core and cavity.

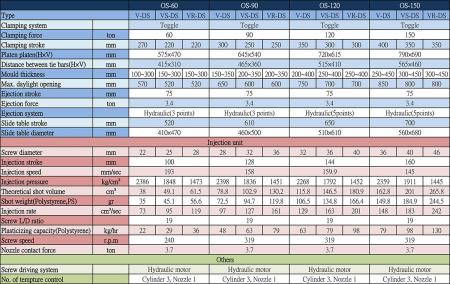

If you need more detail of model specifications, please reach out to us.

Vertical Injection Machine, Toggle Injection Molding Machine, Servo Hydraulic Injection Molding Machine

Plastic Injection Molding Machine Core Features

- Toggle Clamping System clamping force from 60ton - 150ton.

- The unique Platen Lift System design to shorten the clamping time. It reduces the burden of the toggle that enables to increase the lifetime.

- Our Toggle Clamping design reaches high-speed and smooth during the clamping, and also depend on the different molds require even to reach the low-pressure clamping, which is different from the Hydraulic Clamping (Diagram 1).

- Dual injection cylinders mechanism provide high-pressure and high-speed of injection.

- The unique design of the injection unite, the hydraulic charging motor could turn 180 degrees from the original position, which makes you easier to change the material tube (Diagram 2).

- The strong injection structure keeps the stabilization of the injection unite when the hydraulic motor is charging.

- Optional slide table or rotary table for added safety and productivity.

Your Benefits of purchaseing Plastic Injection Molding Machine

- The first choice for automated precision molding products.

- Easy to establish the connection to the automated production equipment.

- Customized design according to the product enables to meet the diversity production line.

- Suitable for insert molding or overmolding.

- Low noise, only 63 dBs under the high load condition.

- Particularly space-saving.

Our Advantage

- DS series injection machine comes standard with high-performance close-loop energy-saving servo motor, compared with conventional motor save energy by 60%.

- The platen uses the FCD-600 spheroidal graphite cast iron could achieve 600 ~ 750 N/mm² tensile strength not easy to bend or deform.

- The toggle automatic centralized lubrication system, always keeps the toggle and copper bushing parts lubricated to increase the life-time.

- Dual injection cylinders mechanism provides high-pressure and high-speed injection, match with the high response valve upgrade the performance of injection.

- The Mold Adjustment Mechanism with sturdy gear and high torque hydraulic motor has high strength and low clearance, which reduces adjusting time and increases accuracy.

- Mold Adjustment Motor with Brake Unit always keeps the platen in the same position prevents to cause the flash of the products.

- The feature of the toggle the max. daylight (distance of mold opening) is always the same won't be affected by the size of the mold.

- The slide table check device makes sure and keeps the mold at the clamping position to prevent the error happen. Raise the stabilization of automated production.

- The safety light curtain, semi auto Two-hand starter bottom, emergency lift up etc. safety device.

Vertical Toggle Hybrid Plastic Injection Molding Machine Gallerys

- Top Unite Vertical Toggle Hybrid Injection Molding Machine.

- Top Unite Vertical Injection Molding Machine slide plate and the platen.

- Top Unite Vertical Injection Molding Machine slide plate.

- Top Unite Vertical Injection Molding Machine clamping structure.

- Product Application

- Specification Table