The High-Efficiency Synchronous Plastic Injection Molding Machine

EHIII Series (50~750 TON)

The high-efficiency synchronous plastic injection machine is designed to meet the comprehensive needs of customers for cost, production capacity, and stable production process. The injection unit and clamping unit are individually controlling by a dual hydraulic system, these two systems could synchronize dosing and mold-opening to match a perfect production timing. Through comprehensive structural improvements and system upgrades, this model can significantly reduce production costs, shorten production cycles and rising output. If you need more detail of product information or buying consultation, please contact us.

Plastic Injection Molding Machine Core Features

- Clamping force form 50ton - 750ton.

- High rigidity Mold Platen design.

- Precision hydraulic circuit and IPC system.

- High-speed injection unit.

- The High-efficiency Synchronous machine action.

Your Benefits of purchaseing Plastic Injection Molding Machine

- The high-efficiency synchronous machine action can significantly shorts production cycle time and rising output.

- Quick and Easy to integrate to the automated production equipment.

- Fast response and precision.

- Significantly reduce machine maintenance costs.

Our Advantage

- FCD-600 spheroidal graphite cast iron with thicker plate achieves 600 ~ 750 N/mm² high tensile strength. Under extremely high injection pressure and speed situation, prevent any bending or deforming to ensure no flash causes on the products that raise the production yield rate.

- The injection molding machine by using logic hydraulic control that raises the efficiency of hydraulic force in the manifold to achieve high speed and precision on the mechanical machine operation. Via the high-response IPC system to calculate every moment of the injection stage setpoint and excite hydraulic valve to complete a high-repeatability production cycle.

- The high-speed injection unit establishes a hydraulic accumulator to boost up injection, we can pressurize this device with hydraulic oil to an upper limit pressure of 160kg/cm² before injection. During the injection, this extra pressure and flow boost up the speed to reach 380mm/s that easy to reach the produce condition of thin-wall products required.

The High-Efficiency Synchronous Plastic Injection Molding Machine Video

Related Application

The high-efficiency synchronous injection machine is suitable for the production of food container, plastic disposable tableware and plastic screw bottle cap.

- Product Application

- The synchronous injection machine can quick and easy to integrate to the automated production equipment.

- Synchronous injection molding machine is used in IML industry.

- Customized the machines to build up a perfect IML injection molding production line.

- Provides the IML injection molding turn-key solution to clients by our abundant experience.

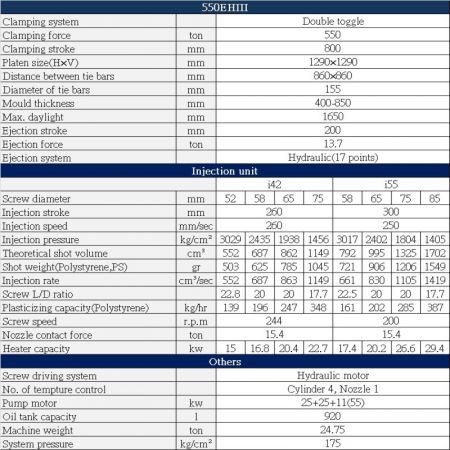

- Specification Table

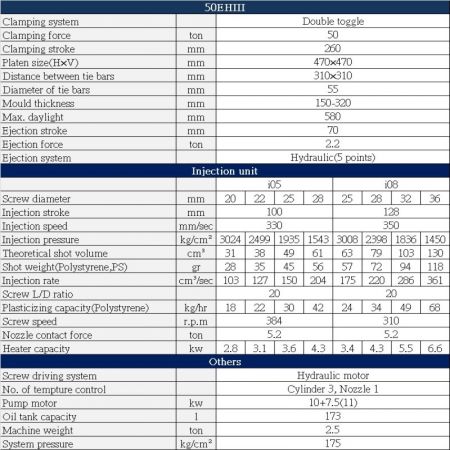

- EHIII 50 ton Specification Table

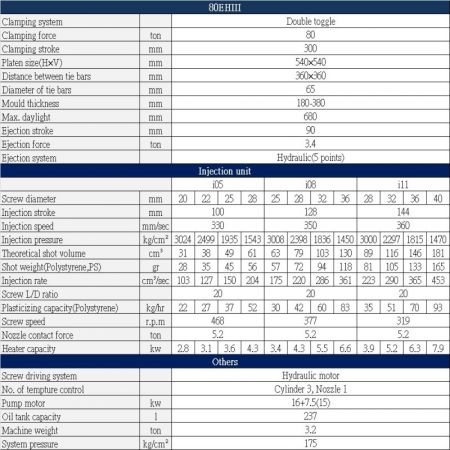

- EHIII 80 ton Specification Table

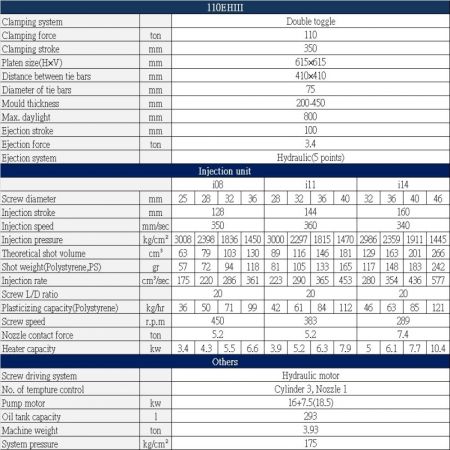

- EHIII 110 ton Specification Table

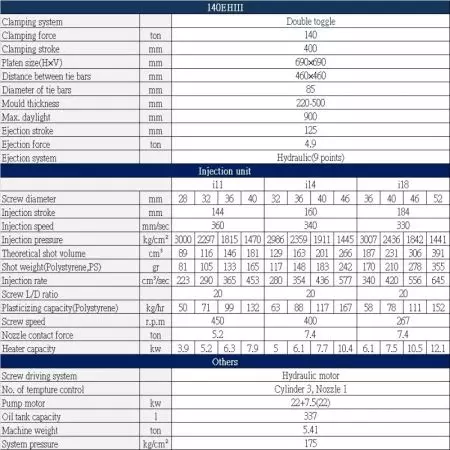

- EHIII 140 ton Specification Table

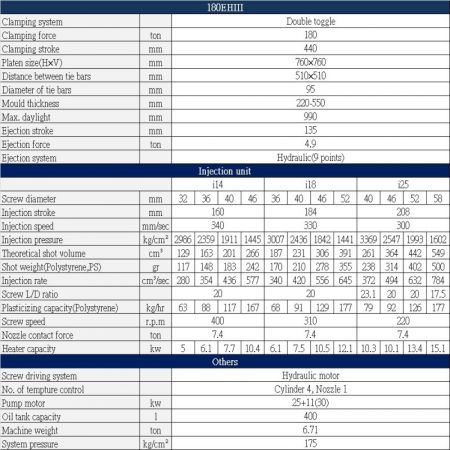

- EHIII 180 ton Specification Table

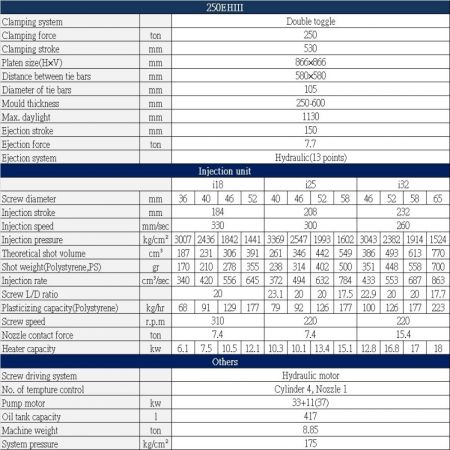

- EHIII 250 ton Specification Table

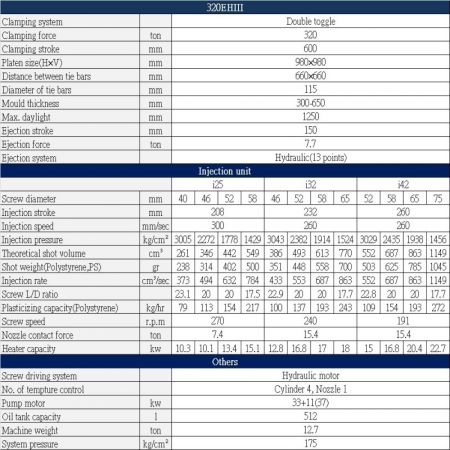

- EHIII 320 ton Specification Table

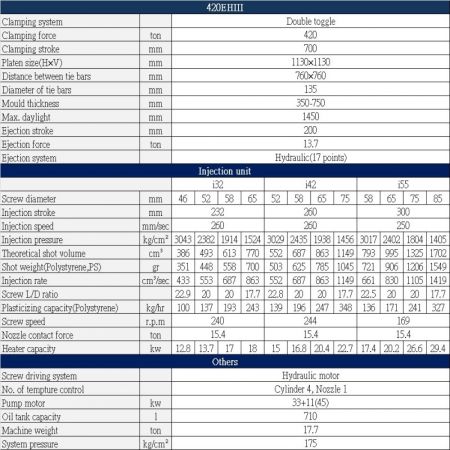

- EHIII 420 ton Specification Table

- EHIII 550 ton Specification Table

- Related Products

Thin-Wall Plastic Injection Molding Machine

EHIII-DS Series (50~750 TON)

Thin-wall plastic injection molding machine is manufactured by increasing the injection speed and the stability of injection, the thin-wall injection machines effectively avoiding short shots and flashes on the product to improve product quality.We upgrade the thin-wall injection machines control components to get a higher injection speed that ensures the injected melting plastic material could reach the entire mold cave before it getting solidification which decreases the short-shot products happened. If you need more detail of product information or buying consultation, please contact us.

Small Size High Speed Plastic Injection Molding Machine

EHIII SERIES (50~140 Ton)

The small high-speed plastic injection molding machine is from 50 tons to 140 tons. It comes standard with a high-response servo valve and accumulator. During the assistance with the accumulator, the injection rate can reach 360mm/sec. The high-response servo valve detects the actual pressure and position of the injection by the transducer and then catches the feedback signal to adjust the output to reach a perfect closed-loop control. By the precision control of the injection, plasticizing, and holding switch-over to prevent causing flash or short-shot. If you need more detail of product catalog, please reach out to us.